Laser Welding Machine

Easy Opetation

The laser welding machine has the advantages are simple operation, welding seam beautiful, fast welding speed and no consumables. Welding in thin stainless steel plate, iron plate, aluminum plate and other metal materials can perfectly replace the traditional argon arc welding and electric welding technology.

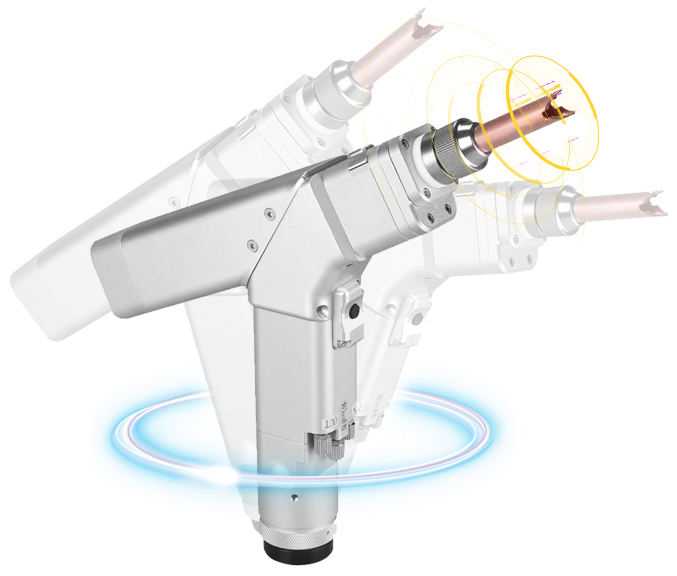

Worble Laser Head

Hand-held swing welding mode, light and flexible.Interactive control system; makes the light spot larger, the welding seam better formed.Lighter weight, ; ergonomic design can be equipped with a variety of angle nozzles to meet the welding needs of different products.

360 Degree Welding

After the laser beam is focused, a small spot can be obtained, which can be accurately positioned and used in the group welding of micro and small size workpieces for mass production. Mainly for the welding of thin-walled materials and precision parts, it can realize spot welding, butt welding, stack welding, sealing welding, etc., high aspect ratio, small weld width, small heat affected zone, small deformation, fast welding speed, no need to be processed after welding or simply processed.

Industry Applications

The laser welding machine widely used in cabinet kitchen, staircase elevator, shelf, oven, stainless steel door and window guardrail, distribution box, stainless steel furnishings and other industries.

Technical Parameters

| Machine Model | Hand-held fiber laser welding machine |

| Laser Power | 1000W 2000W 3000W(optional) |

| laser wave length | 1070 NM |

| Fiber length | Standard10M / Maximum 15M |

| Welding speed range | 0~120 mm/s |

| Cooling chiller | Industrial water chiller |

| Working environment temperature range | 15~35 ℃ |

| Welding thickness recommendations | 0.5-3mm |

| working voltage | 220 V |